Thanks to donations from

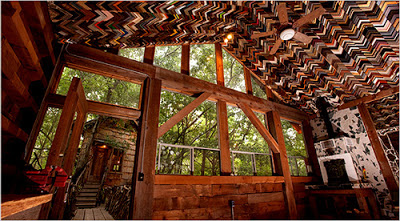

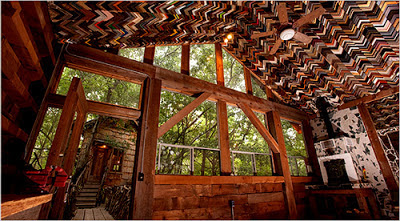

Focal Point Custom Framing and Fort Drum, Better Farm's Art Barn is about to have a gallery ceiling fittingly made entirely out of upcycled picture frames. It's a lesson in upcycling, but more than that we like to think of it as a very literal intersection between art and sustainability. In return for keeping hundreds of old picture frames out of burn pits or landfills, we get to use them to create a thing of beauty—and a thought-provoking thing at that.

|

| The gallery space in Better Farm's Art Barn. |

Since I moved to

Better Farm in 2009, the

Art Barn overhaul has been one of our biggest and ongoing projects. We've cleared out years' worth of hay from the second story, added bank after bank of windows, rented dumpsters to haul out all the old and broken stuff that had been piled up over the course of decades, added track lighting and gallery walls, and turned the whole space into a studio and art and performance gallery. In the fall of 2011 we added recycled soy sprayfoam insulation on the first level, and in the spring of 2012 added a second-story deck overlooking a natural amphitheater (to check out the unreal sound quality for yourself, be sure to visit us at this year's

betterArts/Better Farm Open House & Fundraiser.

I've been kicking around a bunch of ideas for the ceiling on the first floor of the Art Barn, which

betterArts uses as its gallery space:

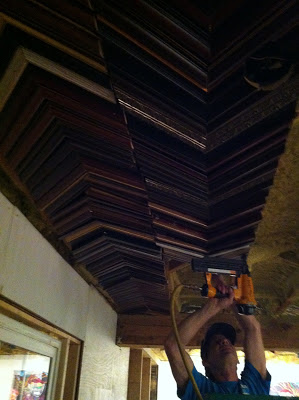

I considered using old barn wood, then wondered about using some old siding we have in the wood shed. Many people suggested sheet-rocking it, or zipping down some slab wood to use. Then, Fort Drum donated a bunch of old, broken picture frames to us. I recalled an article in the New York Times about

Dan Phillips of Phoenix Commotion, a man who builds recycled houses—which is to say, he takes building materials destined for the dump and builds homes with them for next-to-nothing.

In one of the images from that article (see above), he took picture frame corners to create a zig-zag pattern across the ceiling of a house. This was the perfect solution for our Art Barn ceiling! I set about finding a frame shop locally that might be willing to donate more frames to betterArts to use in the non-profit's gallery space.

Tracy Spencer from

Focal Point Custom Framing in Watertown was extremely gracious and said that while

the company seldom has

broken frames, they do have some small frames with defects and discarded moulding. I met with Tracy Saturday morning and picked up the bounty—we're hoping to continue working with

Focal Point in the future to get the project completed (many frame pieces are required!). Tracy also through in some beautiful suede matboard that we can use for arts & crafts projects in the community.

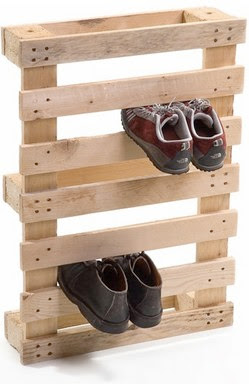

Here's Focal Point's display wall, also indicative of what our ceiling will look like:

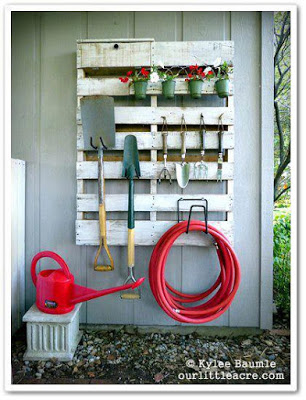

My car, stuffed to the gills:

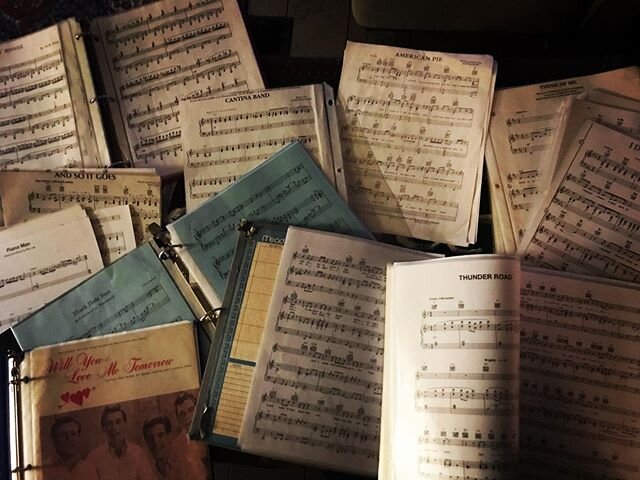

Back at the Farm, I got the Ryobi chop saw out and ready to make 45-degree cuts on the frames:

Then began the extremely tedious process of piecing all the frames together:

We will get chopping this week and should be able to get a quarter to a full half of the ceiling completed before the open house in May. Stay tuned for updates!